Royal Carriage Factory

Royal Carriage Factory

The Royal Carriage Factory, on the right half of the picture, was originally built before the American Revolution. During the Napoleonic Wars it was expanded, and steam power was first used. The building on the left is the mounting shed.

Carriage Manufacture

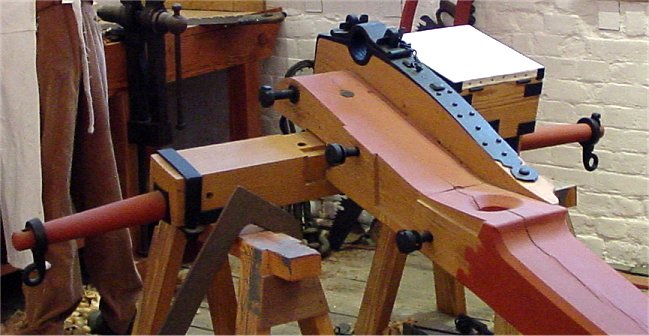

The two above pictures are from the Royal Armouries in Ft. Nelson near Portsmouth. The text below is from the museum display and describes the work that took place in the Royal Carriage Factory in Woolwich. The carriage shown is for a 9 pounder of the Napoleonic era.

"These carriages were built of wood with iron fittings and their manufacture required the skills of wheelwrights, carpenters, and blacksmiths. From the 17th century, the Board of Ordnance in England employed a master carpenter to oversee their manufacture in government workshops or by private contractors, but by the early 19th century, the Royal Carriage Department had been established at Woolwich to centralise design and manufacture."

"Wooden gun carriages combined various materials in a careful blend of lightness and strength. They needed to be light enough to have the mobility expected of them and strong enough to carry the weight of the gun, withstand the strains of firing and survive travelling over rough ground. Their building, therefore, required great care."

"Nor were they as simple as they might seem. Although constructed of wood, the 9 pounder carriage seen here is built with almost engineering precision. The cheeks or brackets which fit on either side of the trail and carry the barrel are not simply bolted on. They are cut with steps on the inner face to engage with recesses on the trail to prevent them moving out of alignment and affecting the aiming of the gun. The wooden bed which partly encases the axletree must be accurately fitted into the underside of the cheeks and trail, suitably cut away to receive it, otherwise the carriage will lean to one side. All wooden parts have to be shaped to receive any metalwork which is fitted and, likewise, the metalwork has to be carefully made."

"The wheels are, perhaps, the most vital parts. The spokes and felloes all have to be of exact size so that when fitted together the wheel is truly circular with the hub at its center. The iron tyre has to be the correct tight fit on the wheel. The pipe boxes (conical inserts in the hub) have to fit the tapered arms on the axletree. These details made a strong and serviceable wheel."

"Oak was preferred for the construction of nearly all the carriage but elm was sometimes used for the brackets. Elm was always used to make wooden hubs, or naves, of wheels because of its resistance to splitting, whilst ash was used for the felloes because of its resilience."

"Whether it was a gun carriage or a simple barrow for moving projectiles which was being built, the work in the Royal Carriage Department was carried out to the highest standards. Only after ensuring that these standards had been achieved was the product accepted as fit for service."